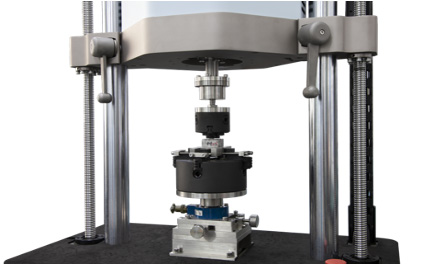

ProSim Mechanical Wear Simulators for Industrial and Medical applications

'Simulate to evaluate' Improving longevity

Since 1993

Hello! We are ProSim

Since the 1990s, Prosim—a division of the Simulation Solutions Group—has been at the forefront of orthopedic implant wear testing through a long-standing partnership with the University of Leeds. Together, we’ve developed advanced wear and fatigue simulators that support one of the world’s largest independent testing labs, with over 100 stations of testing capacity for hip, knee, ankle, shoulder and spinal implants.

Today, Prosim offers a comprehensive suite of electro-mechanical simulators for both medical and industrial tribological and wear fatigue testing. Our flexible, cost-effective approach has enabled us to expand into both mature and emerging global markets. We work closely with customers and academic partners to design simulators that exceed appropriate standards—replicating real-world conditions, wider ranges of motion, and higher loads to better understand adverse wear. At the heart of Prosim is a 30-year legacy of innovation, trusted collaboration, and a relentless drive to push the boundaries of fatigue research.