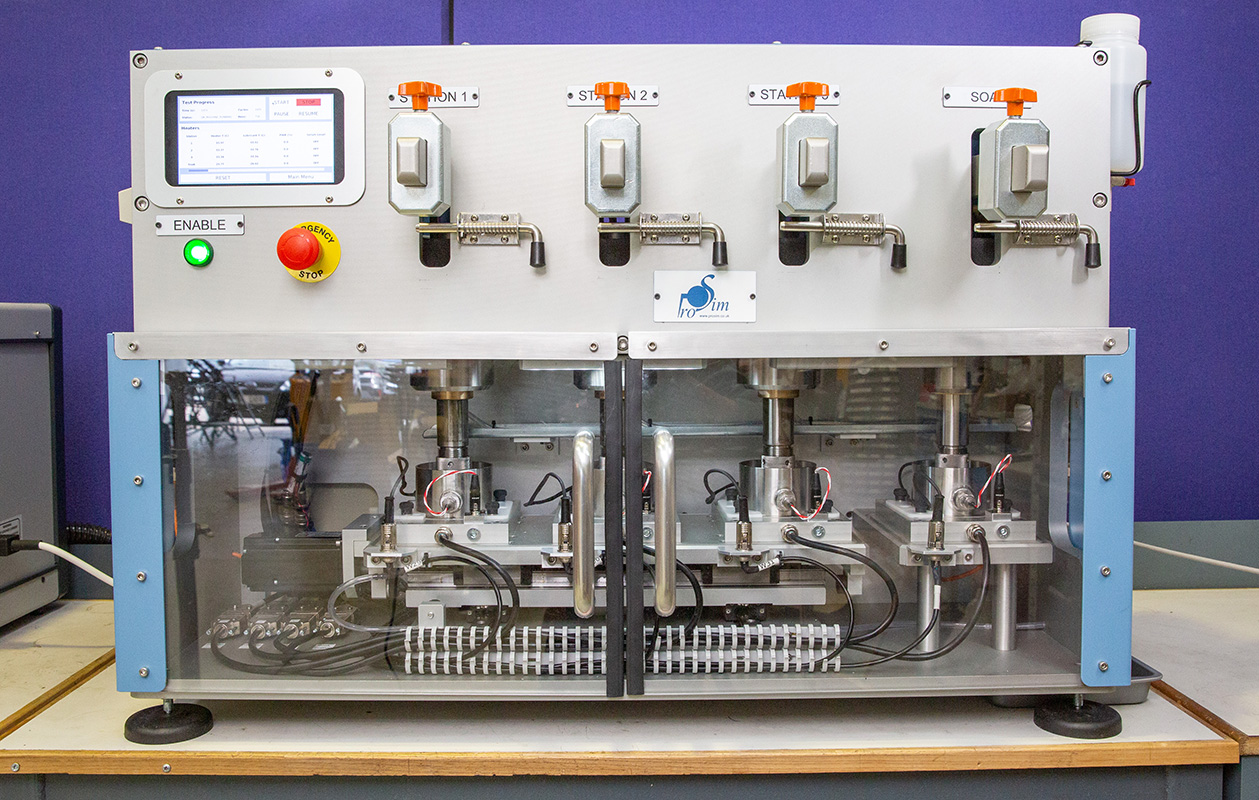

The Prosim Pin-On-Plate Tribometer is a multi-station machine designed for the reliable and repeatable study of the wear of bearing surface materials, providing designers and developers of orthopaedic implants with a cost-effective and accurate means of generating wear of specific bearing surface combinations, under different conditions.

The Pin-On-Plate Tribometer

All controlled axes of the Prosim Pin-On-Plate Tribometer are electromechanically driven, using a combination of motors, drives and gearboxes. This enables the simulator very closely follow any demand waveform however demanding it may be.

Empirical data generated by our simulators over the last 25 years supports the assertion that the patterns of wear of implants tested in Prosim Simulators accurately mirror that of the wear of implants extracted from humans after years of use.

The Prosim Pin-On-Plate Tribometer includes numerous features and benefits:

- Meets the apparatus requirements set out in ASTM F732-00 (2011) – Wear Testing of Polymeric Materials Used in Total Joint Prostheses

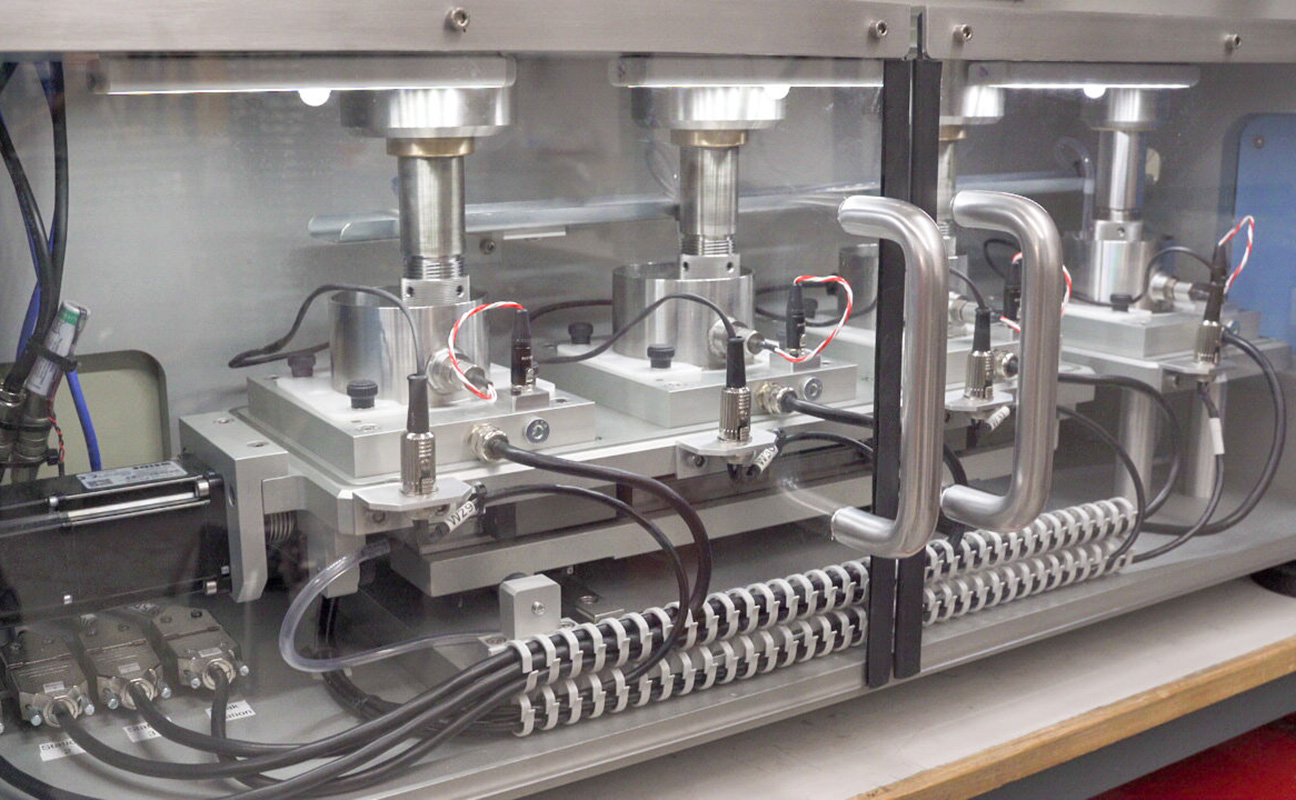

- Configured as a three kinematic stations – allow programmable X-Y motion of a counterface against a programmable static or rotating pin plus one soak station – pin against a static counterface

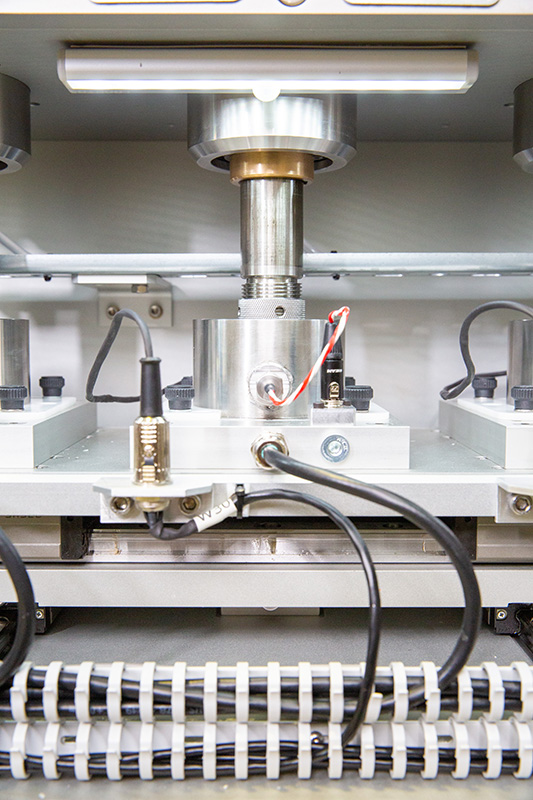

- The counterface on the kinematic stations has a sinusoidal range of motion up to 25mm in both X and Y directions, linear, circular or elliptical motions in either X or Y directions.

- The pins on the kinematic stations rotate at the same rate and are programmable up to 120 RPM.

- The user adds static mass (up to 300N) to provide axial loading (Z axis).

- The frequency of motion is programmable up to 2Hz

- The lower surface of the sample cup has an integrated heater and temperature control system that maintains the lubricant temperature at 37°C +/- 2°C

- A station-specific valve topping-up system maintains the lubricant levels

Custom simulators.

Prosim is able to offer customisation of its simulators to meet the client’s specific testing requirements, including additional stations and different configurations (i.e single bank of six stations, two banks of three stations, etc).

Hope for people with severe spine fractures

Leeds University is at the forefront of research into implant technology and that research is just about to take a big leap forward in the

ISO Electro-Mechanical Wear Simulators – The New Focus for Prosim

Feb 11, 2009 Following the successful introduction of the spinal implant wear simulator, their first fully electro-mechanical simulator, Prosim have now committed to a development

Prosim Appoints A Chinese Distributor

Feb 11, 2009 In order to capitalise on the potential of the Chinese orthopaedic market and its growing requirement for testing equipment to ensure that